Founded in 1995, Datt Mediproducts Pvt. Ltd. started its journey as an Export Oriented Unit dealing in medical textile disposables. For the last 17 years, we have been providing our services to the medical industry. We now sell our products all over India as well as overseas also.

Quality Products that reach Worldwide

We have loyal customers from all around the world including India, UK, Japan, UAE, Oman, France, Mexico, Germany, Netherlands, South Africa, etc. to whom we export on a regular basis. Our products conform to international standards; at DMP we are very particular about our quality standards and always strive towards ensuring uncompromised adherence to quality control.

Our Certification Speaks

DMP has a certified ultra-modern plant situated 60 km away from Delhi. Honored by New Materials Award from Textile Institute – Manchester, Star Export House by Ministry of Commerce, Government of India, also certified by ISO 9001, ISO 13485 & MDD93/42/EEC and audited by SGS, 202B Worle Parkway, Weston-super-Mare BS22 6WA, United Kingdom and GMP.

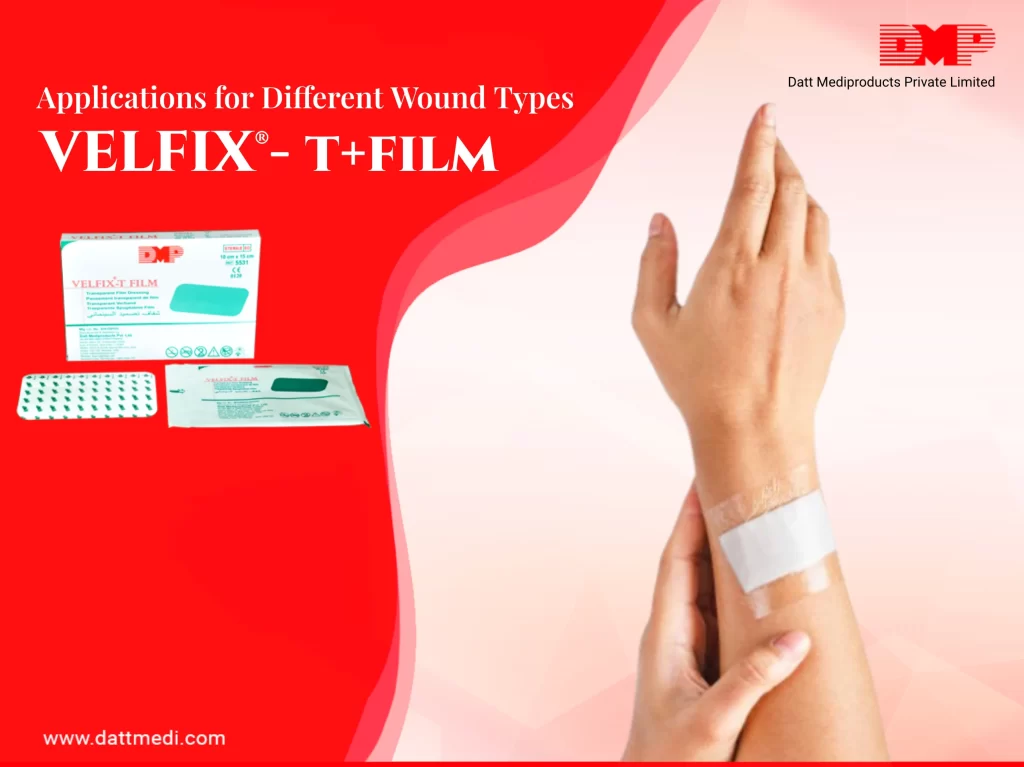

In this new age of technology, we have launched several advanced products in the market. We manufacture wound care and advanced wound care products, which include

– Bandages

– Tapes

– Dressing kits

– Biodegradable Nasal Dressings

– Biodegradable Hemostat Dressings

– Negative Pressure Wound Dressings

Specialize in Research and Development

With a Government recognized (DSIR) cutting-edge research and development center in the premises, the team is committed to make efforts to progress in healthcare, biotechnology and in the bio-medical field. These activities carried continuously to enhance and optimized products help us to deliver next generation healing solutions worldwide.

Vision, Mission, and Values that sets us apart

⁃ We foresee Datt Mediproducts to be a leading global company in the Medical wound care industry. ⁃ We aim towards improvisation of healthcare through innovation. ⁃ We follow work ethics by creating surroundings that encourage creativity and welcome new ideas leading to advancement in skills, technology and processes.

Customer satisfaction is our primary motto. We at DMP, manufacture a wide range of next-generation healing products for the quick healing of the wounds. These products are supplied to all the nursing homes and hospitals regularly. Innovative products designed by us are catering to the ever-increasing demands of the healthcare sector.

Visit www.dattmedi.com to know more about us.